Address

Fujian Province Jinqiang Machinofacture Co.,Ltd., Rongqiao Industry Park, Nan’An, Quanzhou City, Fujian Province, China

Work Hours

Monday to Saturday: 9AM - 6PM

Sunday: 10AM - 5PM

Address

Fujian Province Jinqiang Machinofacture Co.,Ltd., Rongqiao Industry Park, Nan’An, Quanzhou City, Fujian Province, China

Work Hours

Monday to Saturday: 9AM - 6PM

Sunday: 10AM - 5PM

Installing truck wheels may seem simple—just bolt them on and tighten them. But if not done correctly, it can lead to wheel separation and serious accidents. Proper installation is more than just tightening nuts; it requires following the right steps and avoiding shortcuts.

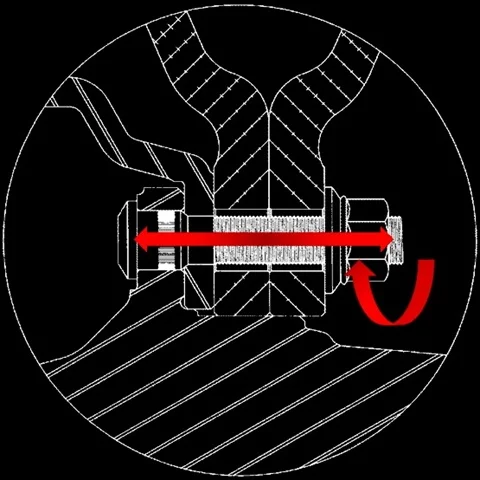

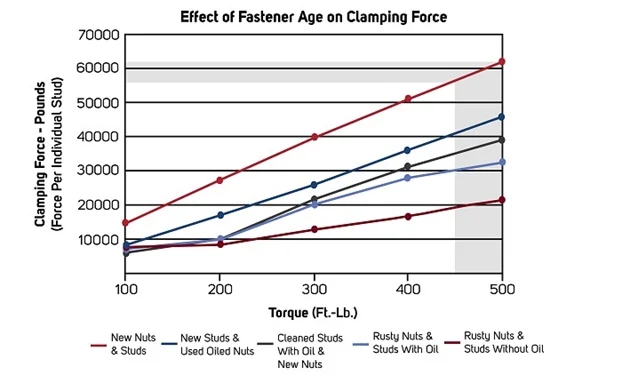

Many people talk about torquing the wheel nuts, but the key factor is clamping force—the pressure that holds the wheel securely. This force depends on the tightness of the bolts and friction levels. Under the right conditions, a properly installed wheel provides strong clamping force, preventing it from coming loose.

Before reinstalling a wheel, always inspect the hardware. Look for cracks, stretched or corroded studs, and elongated stud holes. If a stud is damaged, it may weaken the clamping force and should be replaced.

“Good quality studs last a long time,” says Brandon Uzarek from Accuride. “But if the threads are worn out or stretched, they must be replaced.”

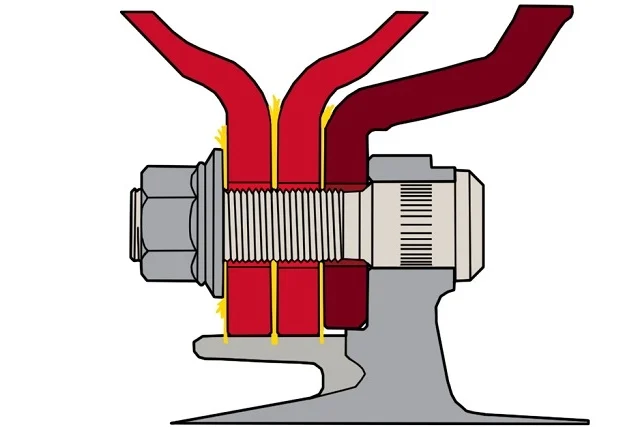

Dirt, rust, and excess paint on the hub and wheel mounting surfaces can weaken the clamping force over time. Loose debris can fall out, causing the wheel nuts to loosen.

Steel wheels with thick paint or corrosion are particularly vulnerable. Experts recommend keeping paint thickness below 3.5 mils, especially on mounting surfaces.

When reinstalling truck wheels:

✅ Inspect and replace damaged studs and nuts

✅ Clean all surfaces to remove rust, dirt, or paint

✅ Apply a few drops of motor oil to studs and nuts to reduce friction

✅ Use a calibrated torque wrench (not an impact gun) for final tightening

Many believe tighter is better, but applying excessive torque can stretch the stud beyond its limit, reducing clamping force instead of increasing it. Always follow manufacturer recommendations for correct torque settings.

After installing a wheel, it should be re-torqued after 50-100 miles. This helps compensate for any settling or debris removal, preventing the loss of clamping force. Regular re-torquing every 10,000 miles is also recommended.

Proper truck wheel installation is more than just bolting them on. Regular inspections, correct torque application, and keeping surfaces clean can prevent loose wheels, accidents, and costly damages. Don’t take shortcuts—your safety depends on it!